Our Produtcs

PELLET MACHINES

PELLET PRESS MACHINE

It compresses the powdered sawdust between the roll and the disc, removes it as a pellet from the holes in the disc and throws it from the pouring nozzle.

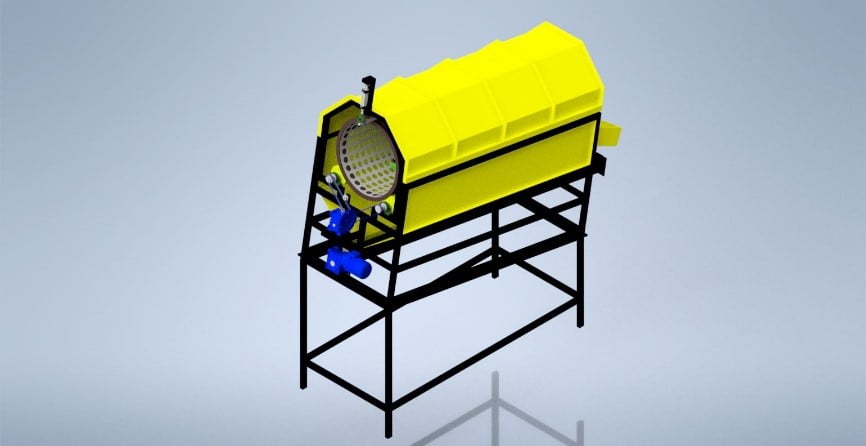

ROTARY ELEK

It sieves the product poured into it with the rotation of the circular sieve and separates it from large pieces and lumps and discharges the clean product sorted by the spiral underneath from the spiral pouring spout on the front side.

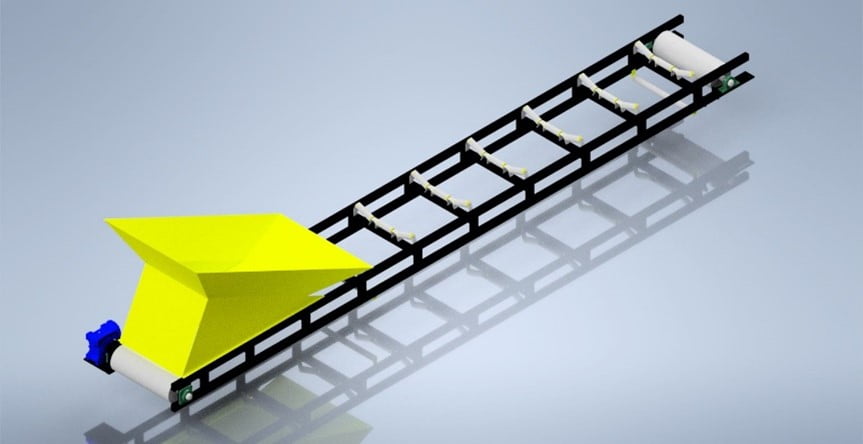

CONVEYOR BELT SYSTEMS

It carries the product falling on it forward along the band.

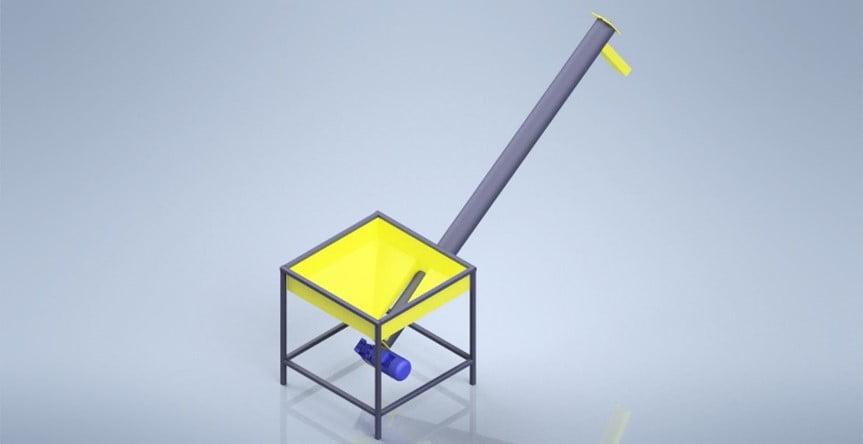

CONVEYOR SCREW

It is our machine that enables the product poured into the hopper to be transported upwards and to a forward point with the spiral system in the pipe. Products that can be used are wood shavings, manure shavings etc. small particle products.

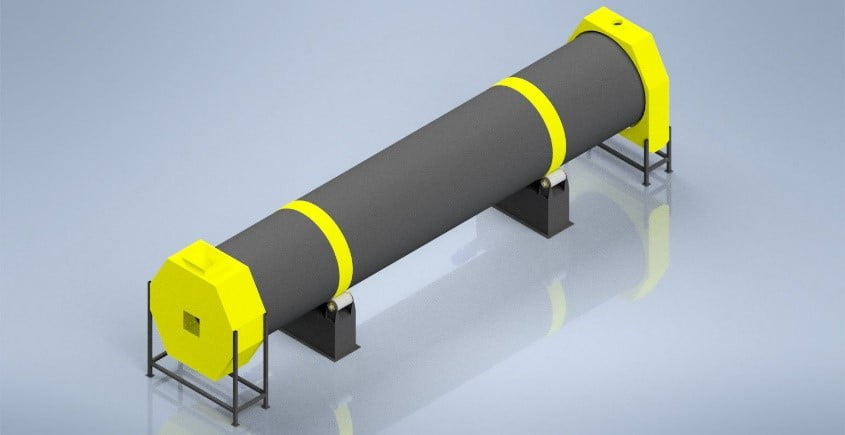

ROTARY DRYER

It dries the moist sawdust poured into it by continuously circulating with hot air and carries it forward.

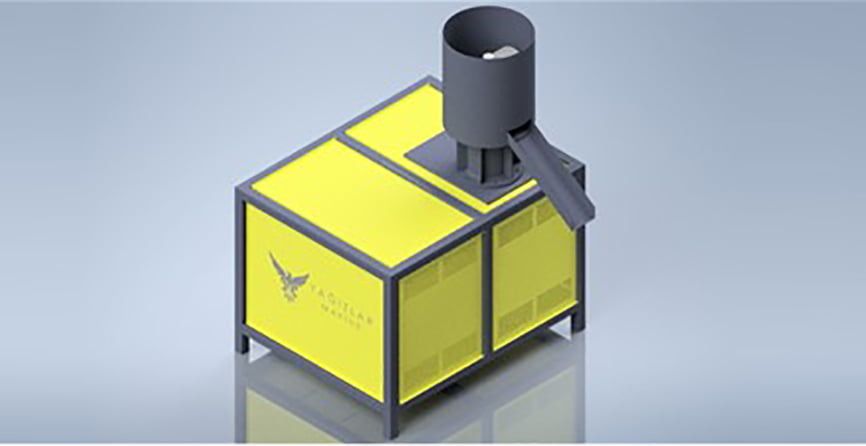

PELET OVEN

The pellet in the pellet hopper is fed into the furnace in a certain amount with a small screw underneath and a stable temperature is obtained with the pellet burned inside, and the temperature obtained by the suction fan is drawn by the air flow and transported to the drying system.

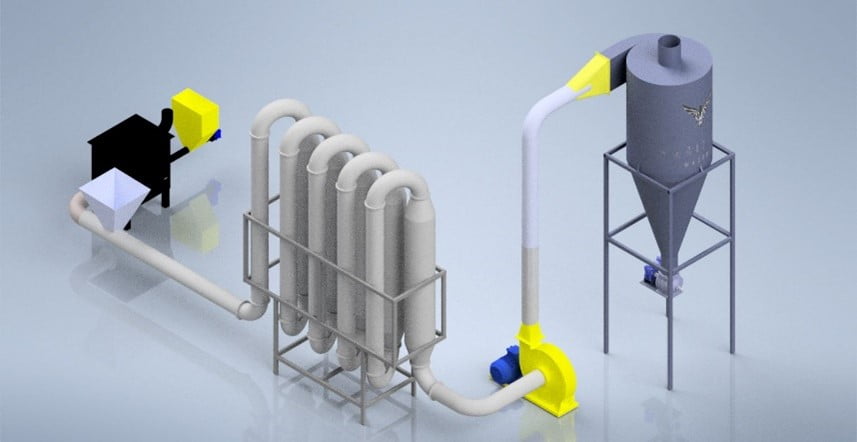

FLASH DRYER

It reduces the humidity in the product by bringing the product together with the hot air flow created in the flash dryer to be supported by the oven and fan.

SUCTION FAN

With the air flow it provides, it draws the sawdust entering the system and carries it to the next section.

CYCLONE

It separates the sawdust carried into it by the fan from the air and discharges a certain amount from the bottom.

SAWDUST DRYING SYSTEM

In the figure, from left to right, you can see the pellet furnace, flash dryer, suction fan and cyclone.

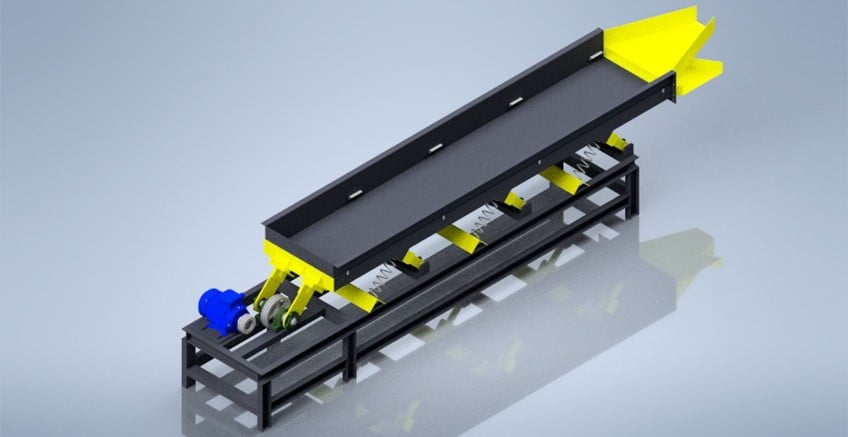

SARSAK ELEK

The pellet falling on it is eccentrically connected to the shaft rotation movement and the machine vibrates in the forward direction, sieves the product and carries it to the pouring mouth and pours it.

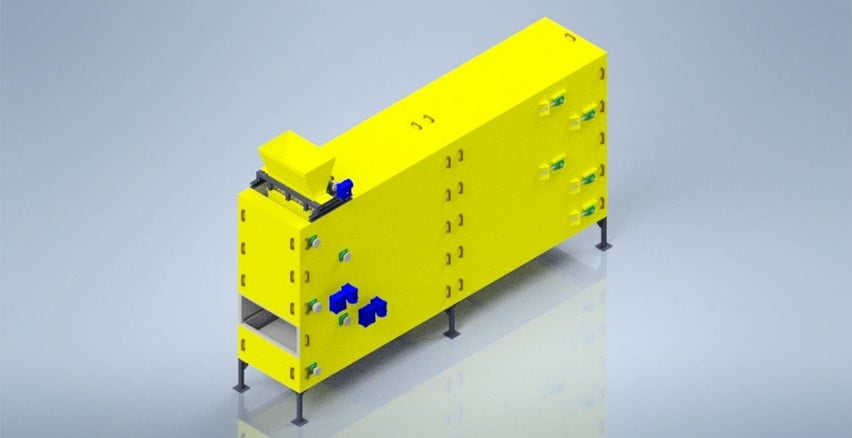

PELLET DRYING OVEN

The pelletised product is poured from the inlet nozzle, keeping it together with the hot air coming into it and pouring it layer by layer, taking the moisture of the product and pouring it from the discharge part at the bottom.

MIXER

It continuously stirs the product poured into it to prevent it from clumping and ensures that it is poured in the same amount from both sides.